Precision in manufacturing is one of the cornerstones of modern engineering. From the automotive industry to aerospace and toolmaking, achieving a flawless surface finish is crucial for both functionality and aesthetics. Among the many machines that make this possible, the surface grinder stands out as one of the most essential tools in precision machining.

What Is a Surface Grinder?

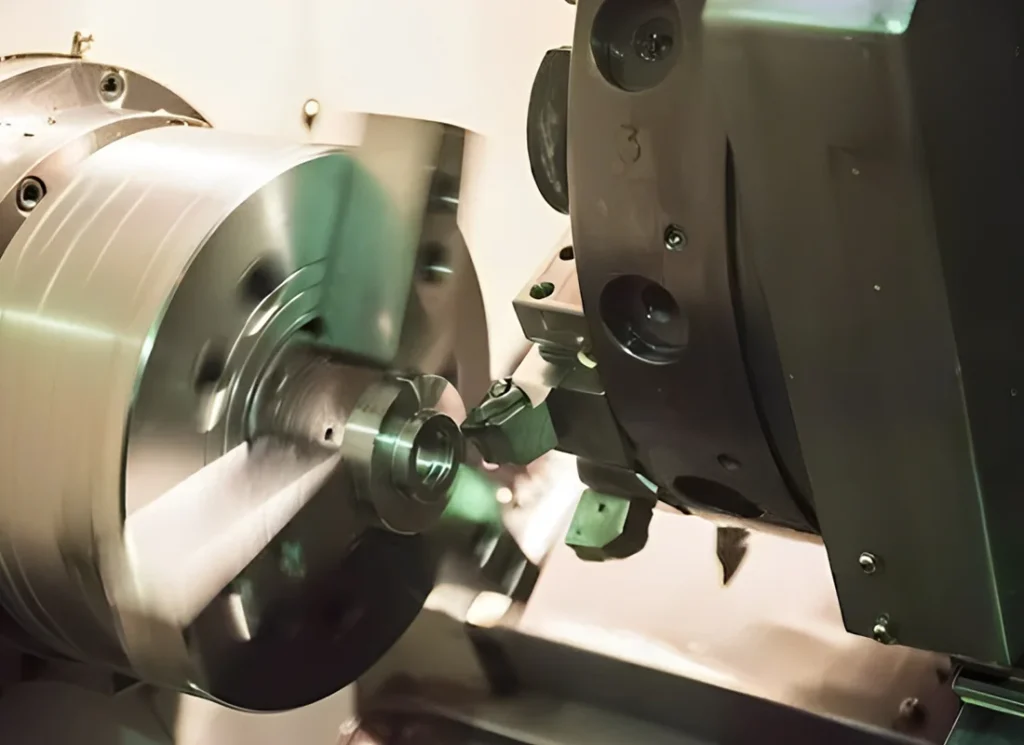

A surface grinder is a machine tool used to produce smooth, flat surfaces on metallic or non-metallic materials. It operates by holding a workpiece securely on a table while a rotating abrasive wheel removes material in small increments. This process ensures an even and controlled finish, ideal for components that require tight tolerances.

The machine typically includes a grinding wheel, a workholding device (such as a magnetic chuck), and a reciprocating table. The operator adjusts the wheel height and feeds the workpiece to achieve the desired thickness and surface finish.

How Surface Grinding Works

The surface grinding process involves three key actions: grinding, dressing, and finishing.

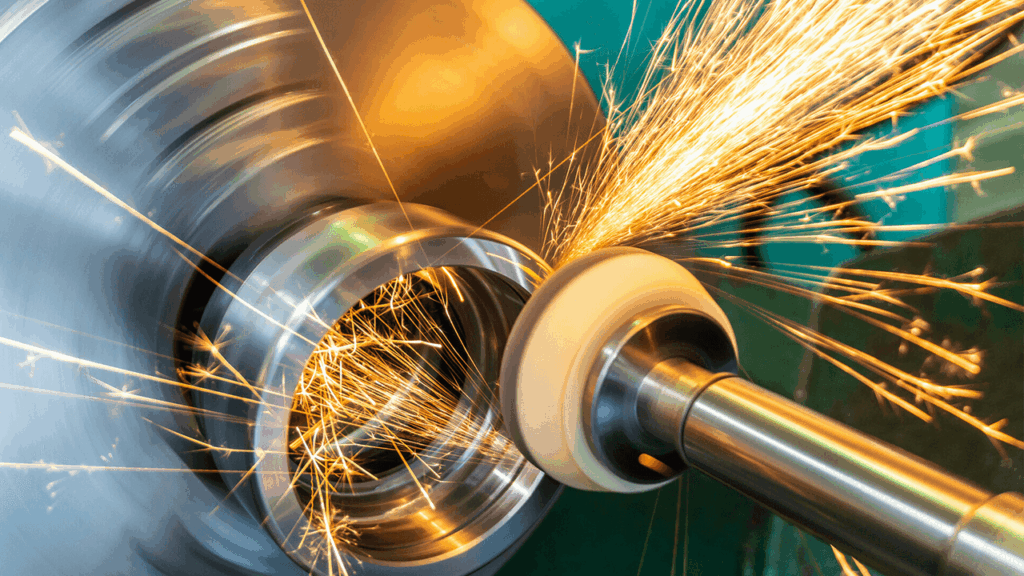

- Grinding: The abrasive wheel rotates at high speed, removing small amounts of material from the workpiece’s surface. The wheel’s abrasive particles act as tiny cutting edges, producing a smooth, uniform finish.

- Dressing: Over time, the grinding wheel becomes worn or clogged with debris. Dressing restores the wheel’s sharpness by removing its outer layer and exposing new abrasive grains.

- Finishing: The final passes of the wheel ensure the surface is completely flat, with minimal imperfections or marks.

This precision allows manufacturers to create components that fit perfectly with other machine parts, reducing friction and wear.

Types of Surface Grinders

There are several types of surface grinders, each designed for specific applications:

- Horizontal-spindle reciprocating table grinders: The most common type, ideal for precision work on smaller parts.

- Vertical-spindle rotary table grinders: Suitable for larger workpieces and provide faster material removal.

- Double-disc grinders: These machines grind both sides of a workpiece simultaneously, ensuring uniform thickness.

- CNC surface grinders: Controlled by computer systems, these machines offer exceptional accuracy and repeatability for high-volume production.

Materials and Applications

Surface grinders are used on a wide range of materials including steel, cast iron, aluminium, brass, and even ceramics. Their versatility makes them invaluable in several industries:

- Automotive: Engine blocks, pistons, and transmission parts require perfect flatness for optimal performance.

- Aerospace: Aircraft components must meet tight tolerances to ensure safety and reliability.

- Toolmaking: Moulds, dies, and cutting tools rely on precise surface finishes to maintain accuracy during operation.

- Manufacturing: Any industry that involves assembly lines or precision machinery benefits from surface grinding technology.

Advantages of Using a Surface Grinder

The surface grinder’s ability to achieve high levels of accuracy and smoothness makes it indispensable. Some of its main advantages include:

- Precision: Surface grinders can achieve tolerances as fine as 0.001 mm, ensuring parts fit together perfectly.

- Consistency: Once set, the machine produces identical results over multiple runs.

- Versatility: Suitable for a wide range of materials and component shapes.

- Improved finish: Produces aesthetically pleasing and functionally smooth surfaces.

Additionally, surface grinding can improve the mechanical properties of materials by reducing stress concentrations and improving fatigue resistance.

Maintaining and Operating a Surface Grinder Safely

Proper operation and maintenance are vital for achieving the best results and ensuring safety. Operators should always wear protective gear, check that the grinding wheel is correctly mounted, and avoid excessive feed rates that may cause overheating or damage. Regular inspection of the machine, lubrication, and cleaning also extend its lifespan.

Before starting, it is crucial to ensure that the magnetic chuck is properly engaged and the workpiece is securely fastened. Coolant should be used to reduce heat and prevent warping of the material.

The Role of Surface Grinders in Modern Manufacturing

As industries evolve and demand ever-higher standards of precision, the surface grinder remains an essential part of modern manufacturing. It bridges the gap between raw machining and finishing, ensuring that every part meets exacting specifications. With advancements in automation and CNC technology, these machines now operate with minimal human intervention while maintaining exceptional accuracy.

Manufacturers across the world rely on surface grinders to improve efficiency and product quality. Whether producing components for engines, medical devices, or high-tech electronics, precision grinding guarantees uniformity and performance.

For businesses looking to invest in industrial equipment, understanding the versatility and benefits of a surface grinder is essential. It’s a machine that not only enhances product finish but also contributes to long-term reliability and customer satisfaction.

Final Thoughts

In a world where precision and quality are paramount, the surface grinder continues to play a vital role. Its ability to deliver consistent, high-quality finishes makes it an invaluable asset for manufacturers aiming to meet demanding standards. As technology continues to evolve, surface grinding will remain a fundamental process, combining craftsmanship with cutting-edge innovation to shape the future of modern industry.