Do you know aluminum can serve as a replacement for wood? It comes with different benefits and is also used for a variety of projects. The wood finish aluminum combines the natural warmth of timber, and it comes with higher durability and performance.

The wood finish aluminum is one of the cost-effective materials, and it will portray the beauty and the warmth of the wood. It is the most preferred material for exterior uses, and the wood-look finish will come for a longer period.

If you are planning to install wood finish aluminum in your home, then get to know about the properties and benefits.

What exactly is wood finish aluminum?

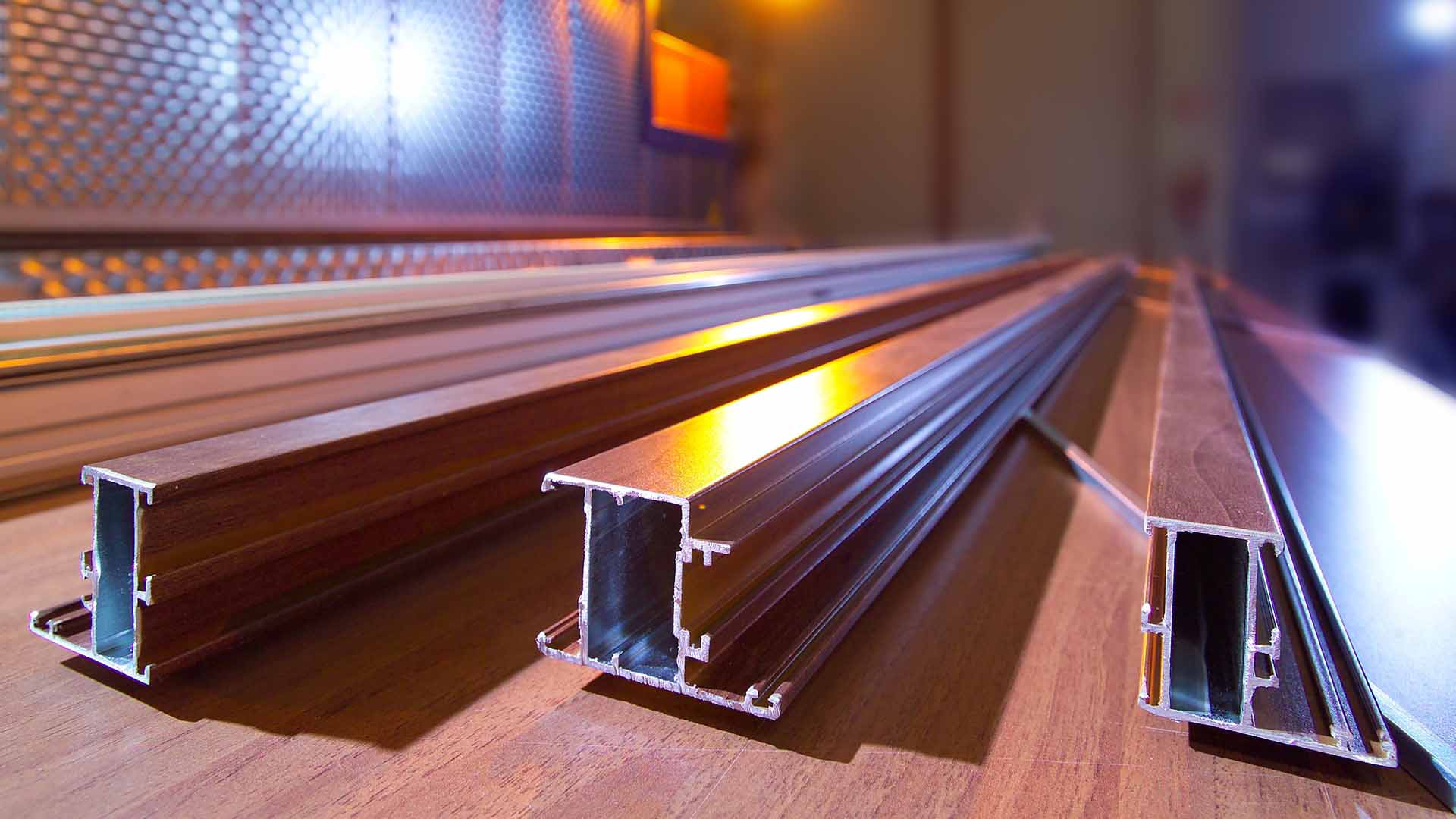

The wood finish aluminum is nothing but a composite of aluminum and it mixes with other materials during the processing. The wood film is laminated on the surface of aluminum, and in the end, it will give a more wood-like appearance. The best part is that you will find different options in the wood finish aluminum, as the color will vary depending on the needs.

This is an environment-friendly solution and also it will give a natural timber appeal, so you can consider this option in the replacement of wood. You can use a wood finish aluminum in the places where you want to use the original wood.

The wood finish aluminum is widely used in applications such as ceiling, door frames, screening, wall cladding, window frames, pergola, siding, decking, and railing.

The wood finish aluminum is better than the natural wood, and if you think how, then here are the reasons;

- The wood finish aluminum comes with high quality, can be installed quickly, and also it can be maintained for a longer time. But the natural woods are heavier and it requires often cleaning

- The wood finish aluminum can be customized depending on the needs of the customer but the real wood offers limited options

- Aluminum wood offers more flexibility when compared to the natural wood

How it is processed?

The aluminum gets the wood finishing look through a heat transfer system, and it is entirely a physical-based reaction. The inks will get into the gas stage from the solid stage, and at precise temperature and pressure, the ink from the paper support will move into the synthetic layer by powder coating, and then the color and position will be fixed.

So, here are the two processes that show how aluminum is getting the wood finishing looks;

The powder coating process three types of steps;

- Base coat

Here, the base coat of powder will be applied to the aluminum extrusion and the powder is electrostatically charged to enhance the adhesion process.

Then, the material will be placed in the curing oven for about 10 minutes and the temperature will be around 2000C.

- Cool down

The final stage is the material will be taken from the oven and it is allowed to cool. Once they are fully cooled, they will be taken to the sublimation process.

- Sublimation

The sublimation is divided into four stages;

- Film wrapping

There will be a film, and even the film with decorative patterns can be chosen, mostly the wood grain for wood finish aluminum. It will be wrapped around the aluminum profile which is completely cooled now.

- Air removal

Make sure that there is any air between the film and the material, as the air should be completely removed for better results. This will make the film stay firm against the coated aluminum.

- Curing

Then you can place the wrapped aluminum in the curing oven. The heating process will make the film get transferred to the aluminum from the film.

- Cool down

Then you can pull the aluminum from the oven and then remove the film. Now, you can see the pattern will be fully transferred to the aluminum, and then finally allow the material to get cool down.

Benefits

Appearance:

This is one of the biggest advantages of the wood finish aluminum as you can use it for both interior and exterior applications. Not only the aluminum but also the packing layers and glue have undergone extreme testing which will result in long-term performance.

High resistance to fading:

If you are choosing any alternate material for wood, then the first thing to consider is the paint’s ability to maintain its color. Most people choose aluminum instead of wood, to avoid the graying process that wood goes through. This type of wood finish aluminum undergoes extreme weather conditions.

Less maintenance:

The wood finish aluminum is a highly durable product so you don’t have to clean the wood often and also the cleaning process is easy. The material is highly resistant to heat, acid, humidity, detergents, salt, and ultraviolet rays.

On the other hand, natural woods require maintenance often and it swells during the monsoon so it needs regular polishing. When it comes to wood finish aluminum, you don’t need to clean more.

Other benefits

The wood finish aluminum will give a warmer look to your space and it will blend with the wooden furniture. When compared to tinder, the cost of the wood finish is less, and also it is available in many colors, so the customer can choose depending on their needs.

Uses:

- Used for the building exterior walls, especially for the outdoor canopies

- Used in the indoor curtain wall and ceiling decoration

- Can be used for museums, stadiums, and plazas

- Used for the opera house and conference hall

- Mainly used for the exterior applications

Source: sculptform.com

Final thoughts

A wood finish to your exterior makes the house look better, but everyone can’t afford it. That is why the wood finish aluminum is considered the better alternative option as it is cost-effective, and also comes for a longer time. Aluminum wood finish is a relatively inexpensive material and also it will go through different stages of the fabrication process.